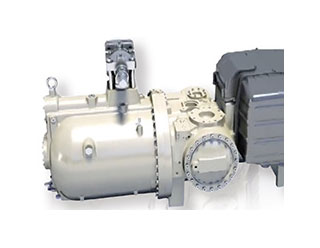

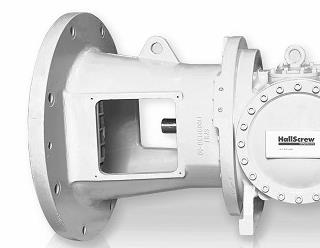

HallScrew Compressors

A comprehensive range of open drive and semi hermetic single screw compressors

More info

HallScrew single screw compressor technology across the complete range

Our HallScrew range has established an enviable track record with HallScrew technology used in over 85 countries worldwide. We call upon unrivalled in-house expertise to set the benchmark for quality, durability and energy efficiency. The range covers single screw compressors, compressor packs and chillers.

A comprehensive range of open drive and semi hermetic single screw compressors

More info

NEW 7200 & 8400 series compressors

More info

With built in Variable Frequency Drive and Variable Volume Ratio

More info

More info

Complete compressor package using HallScrew single screw technology

More info

Air-cooled ammonia chillers using HallScrew single screw compressor technology

More info

Identify HallScrew compressor products for industrial applications

More info

Worldwide J & E Hall and sales representatives

More info

Powering The Cold Chain In Busan

J & E Hall’s HallScrew Technology at the heart of Korea’s modern grocery distribution hub

Read more

J & E Hall HSO3216 compressor for marine refrigeration pack from Sirsa Titanio

J & E Hall’s high-performance HSO 3216 HallScrew compressor has been selected as the core of a newly designed refrigeration pack built by Sirsa Titanio for the King Philip fishing vessel.

Read more