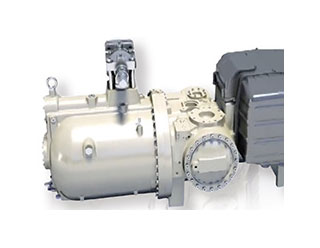

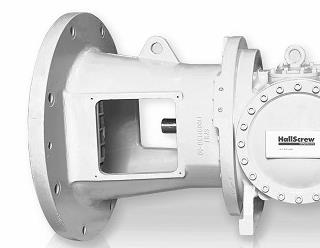

HallScrew Compressors

A comprehensive range of open drive and semi hermetic single screw compressors

More info

HallScrew single screw compressor technology across the complete range

Our HallScrew range has established an enviable track record with HallScrew technology used in over 85 countries worldwide. We call upon unrivalled in-house expertise to set the benchmark for quality, durability and energy efficiency. The range covers single screw compressors, compressor packs and chillers.

A comprehensive range of open drive and semi hermetic single screw compressors

More info

With built in Variable Frequency Drive and Variable Volume Ratio

More info

More info

Complete compressor package using HallScrew single screw technology

More info

Packaged air cooled chillers

More info

Identify HallScrew compressor products for industrial applications

More info

Worldwide J & E Hall and sales representatives

More info